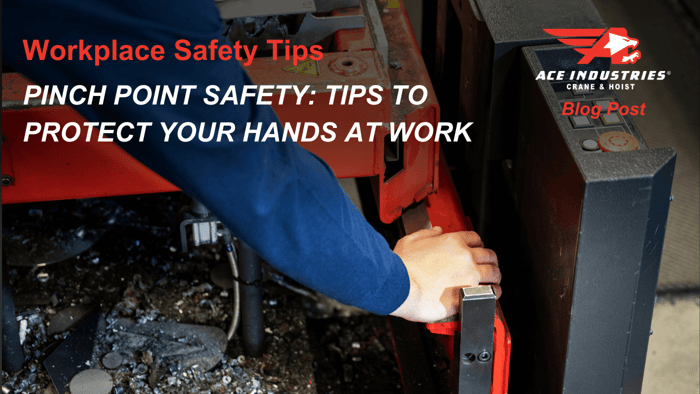

Pinch Point Safety: Tips to Protect Your Hands at Work

Table of Contents

This month, we're focusing on two crucial aspects of workplace safety: pinch point safety and hand safety. Understanding these hazards and taking the right precautions can significantly reduce the risk of injury.

What Are Pinch Points?

Think of a pinch point as any location where a body part can get caught between two or more objects moving together. While they're often associated with heavy machinery like power presses and conveyors, pinch points can exist in many everyday situations on a job site.

Pinch Point Examples:

- The space between materials being unloaded and the surface they're placed on.

- Hand tools like pliers.

- Heavy equipment and its moving parts.

- Concrete blocks and other unsecured materials.

- Chains and pipes being moved or connected.

- Various parts of machinery.

- Even something as simple as a closing truck door and its frame.

Remember, any equipment that transmits energy has the potential to create a pinch point. The severity of injuries from these incidents can range from minor bruises to devastating amputations or even fatalities. Staying vigilant is key.

Common Culprits Behind Hand Injuries

Our hands are essential for almost every task we perform, making them particularly vulnerable to injury. Some common causes of hand injuries include:

- Sharp Tools: Blades, knives, and other sharp objects can easily cause lacerations.

- Machinery: Moving parts present a significant risk of crushing, pinching, and entanglement.

- Hot and Cold Temperatures: Burns and frostbite can occur if hands aren't properly protected.

- Electricity: Contact with live wires can lead to severe burns and other electrical injuries.

- Chemicals: Exposure to corrosive or irritating substances can damage skin.

- Biological Hazards: Contact with contaminated materials can lead to infections.

- Vibration: Prolonged exposure to vibrating tools can cause hand-arm vibration syndrome.

- Gravity: Dropped objects can cause impact injuries like fractures and bruises.

Staying Safe: Tips and Controls

Preventing pinch points and hand injuries requires a proactive approach. Here are some vital pinch point safety tips to keep in mind:

- Avoid Shortcuts: Taking shortcuts often means bypassing safety procedures and increasing your risk.

- Inspect Equipment Regularly: Before use, always check equipment and safety guards to ensure they are in good working order.

- Follow Lockout/Tagout Procedures: When working on or near machinery, always adhere to proper lockout/tagout procedures to prevent unexpected startup.

- Pay Attention to Hand Placement: Be mindful of where your hands are in relation to moving parts and potential pinch points. Never place your hands where you can't see them.

- Wear the Right PPE: Proper gloves and other personal protective equipment are your first line of defense. Ensure your gloves are appropriate for the task and understand their limitations. For example, Kevlar gloves can protect against cuts but not necessarily stabs.

- Communicate with Coworkers: When working together with materials or equipment that could pose a hazard, clear communication is essential.

- Never Leave Running Equipment Unattended: Don't walk away from a machine that is turned on or still coasting.

- Use Tools Wisely: Utilize tools to keep your hands out of the line of fire whenever possible. Avoid using fixed open blade knives; opt for safety knives with retractable blades.

Read more about Safety Tips to Avoid Pinch Point Hazards from Safety International.

Safety is a Team Effort

Remember, pinch point safety and hand safety are everyone's responsibility. From visitors to workers, contractors, and supervisors, we all play a role in creating a safe work environment.

- Regularly review potential pinch point safety procedures with your coworkers and supervisors. Frequent inspections help ensure guards are in place and being used correctly.

- Report any hazards you identify on the job site immediately so they can be addressed.

The Impact of Hand Injuries: The Numbers Speak Volumes

Hand injuries are a significant concern in the United States. Consider these statistics:

- There are approximately 110,000 lost-time cases due to hand injuries each year.

- Around 1,000,000 workers are treated in emergency rooms for hand injuries annually.

- A staggering 70% of workers who experienced a hand injury were not wearing gloves at the time.

- Another 30% were wearing gloves that were damaged or inadequate for the task.

These numbers highlight the critical importance of proper hand protection. Hand injuries can have a devastating impact on an individual's ability to work and their overall quality of life.

Common Types of Hand Injuries

Understanding how hand injuries occur can help us prevent them. Here are three common types:

- Lacerations: These are the most frequent type of hand injury, often caused by contact with sharp objects or tools. Inadequate glove use is a common factor.

- Crush Injuries: These typically happen when hands are caught between two objects or in rotating equipment – classic pinch point scenarios.

- Fractures: These occur due to sudden blows to the hand or fingers, often from vehicle accidents or falls where someone tries to break their fall with their hands.

Key Takeaways

Let's reinforce some crucial points:

- Don't take shortcuts. Safety should always be the priority.

- Practice proper pinch point safety in your work area and around equipment.

- Maintain a team commitment to safety.

- Review Job Hazard Analyses (JHAs) before starting any task and discuss potential pinch points beforehand.

- Be aware of conditions like being rushed, frustrated, fatigued, or complacent. If you notice these in yourself or a coworker, stop and talk through the situation.

Let's all commit to being more aware of pinch point hazards and taking the necessary steps to protect our hands. By working together and following safe practices, we can prevent injuries and ensure everyone goes home safe each day.