A Practical Guide To Choosing The Right Electric Chain Hoist

Buying an electric chain hoist is a smart move when you need reliable, consistent lifting power, but not all hoists are built for the same kind of work. Even a top-of-the-line hoist can feel like the wrong tool if it doesn’t match your job’s specific needs.

We’ve seen it happen: someone installs a single-speed hoist for delicate assembly work, where they actually needed the fine control of dual-speed. The hoist works exactly as it should, but it’s not the right fit, and that leads to unnecessary downtime, frustration, and sometimes even safety issues.

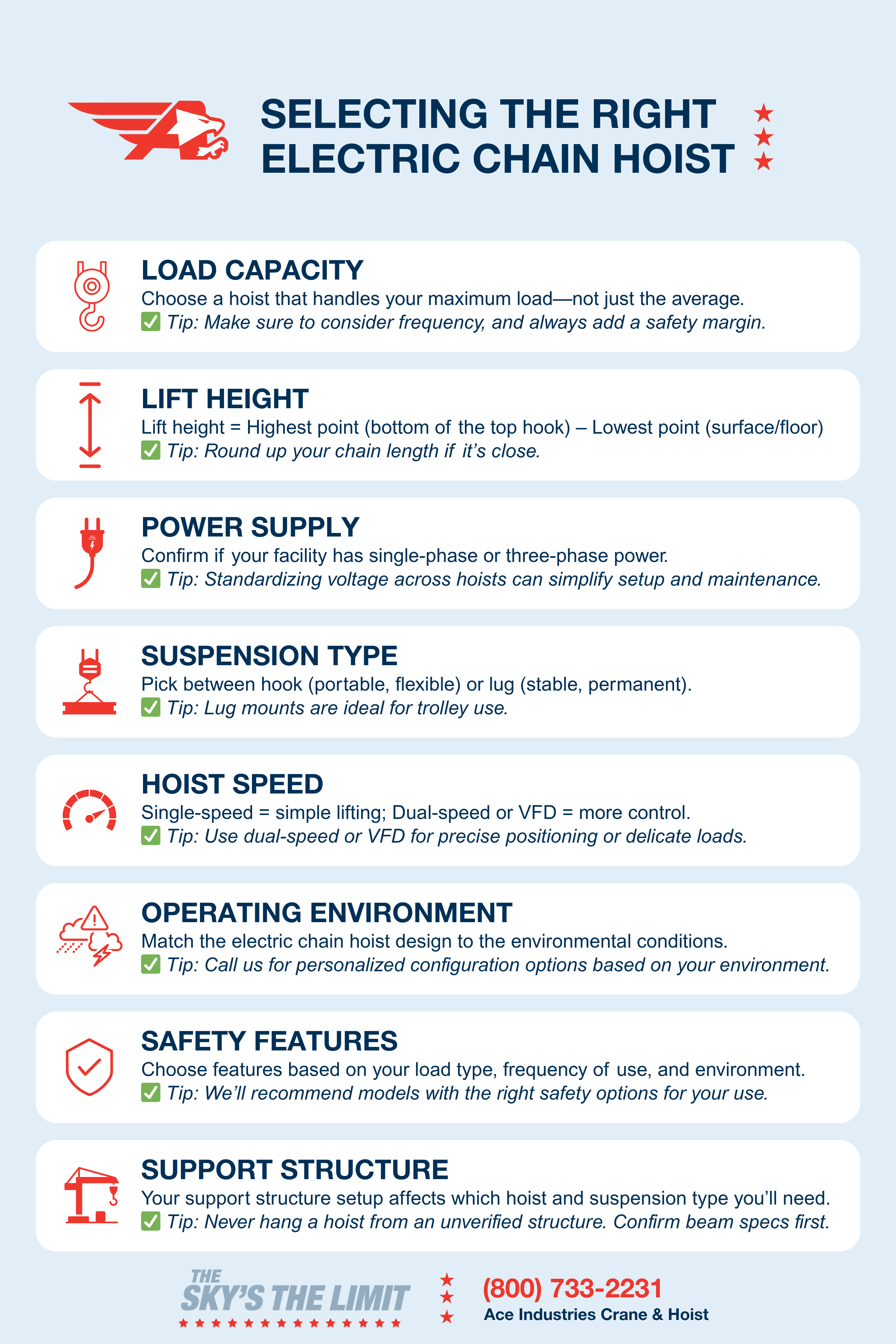

If you already know you need an electric chain hoist, this guide walks you through the most important factors to consider before you buy: things like rated load capacity, lift height, available power supply, suspension type, operating environment, and duty cycle. Our goal is to help you cut through the noise and get straight to the hoist that’s best suited for how, where, and what you’re lifting.

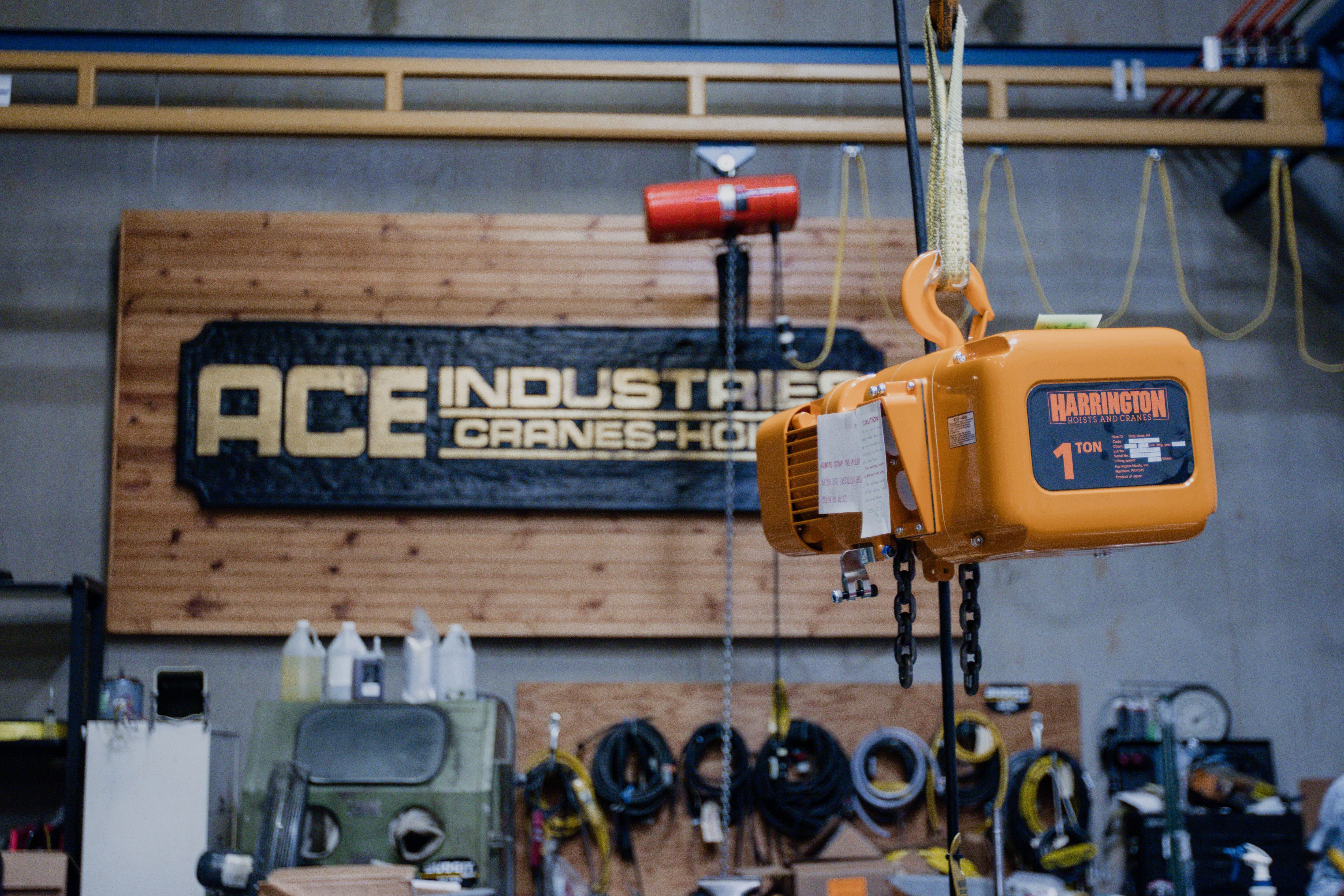

Ace Industries has been in the hoist business since 1932. We’ve worked with electric chain hoists across the entire spectrum, from widely used models trusted in heavy-duty industrial settings to specialized units designed for tight spaces or precise applications, and we know from experience that choosing the right hoist for the job is just as important as choosing a high-quality one.

1. Capacity: How To Know the Right Capacity for Your Electric Chain Hoist

1) Start with The Maximum Load You’ll Be Lifting

Start with the heaviest load you plan to lift using your electric chain hoist. Don’t just average it out. The hoist should be rated to safely handle the maximum weight, not just the typical weight.

✅ Tip: Always include the weight of lifting attachments like slings, hooks, spreader bars, or rigging gear in your total load calculation.

2) Add In A Safety Margin

Industry best practice often recommends choosing an electric chain hoist with a capacity slightly above your maximum load to:

- Protect against overloads

- Account for unexpected load weight changes

- Extend the hoist's service life

Just because an electric chain hoist is rated for 2 tons doesn’t mean it’s built to lift 2 tons nonstop. Think of it like your own strength: if you go to the gym and lift weights, you understand that your one-rep max is not the same weight you'd use for a higher rep set, especially if you're doing this set every day. This same logic applies here—just because your hoist can handle 2 tons doesn’t mean a 2-ton hoist would be able to handle 2 tons all day, every day. This is where duty cycle and frequency of use come into play.

3) Consider Duty Cycle and Frequency of Use

The duty cycle of an electric chain hoist refers to how often and for how long it can operate safely within a given time period. It’s a crucial factor that bridges the gap between rated load capacity and real-world performance.

For example, a hoist rated for 2 tons with a light-duty classification may be perfectly fine for occasional lifts in a maintenance shop. But if you're using that same hoist on a production line where it lifts every few minutes, it will wear out much faster and could pose serious safety risks.

Here’s what to consider:

- Frequency of lifting: How often will the electric chain hoist be used per hour or per shift?

- Length of operation: Are the lifts short and occasional, or part of a continuous process?

- Start/stop cycles: Repeated starts generate heat and wear on motors and brakes.

- Environment and workload: Is the load consistent or variable? Are there shifts with higher loads than others?

Hoists are often rated using HMI/ASME duty classifications (like H2, H3, H4, etc.), which help match the right model to your job’s demands. You can check out this Hoist Duty Classifications guide for reference, but always consult the manufacturer’s specifications or speak with a qualified professional to ensure you’re selecting the right duty class for your specific application.

If you're unsure which duty class your application falls under, our team can help assess your needs and point you to a model built for the job.

2. Lift: Determine the Correct Lifting Height For Your Electric Chain Hoist

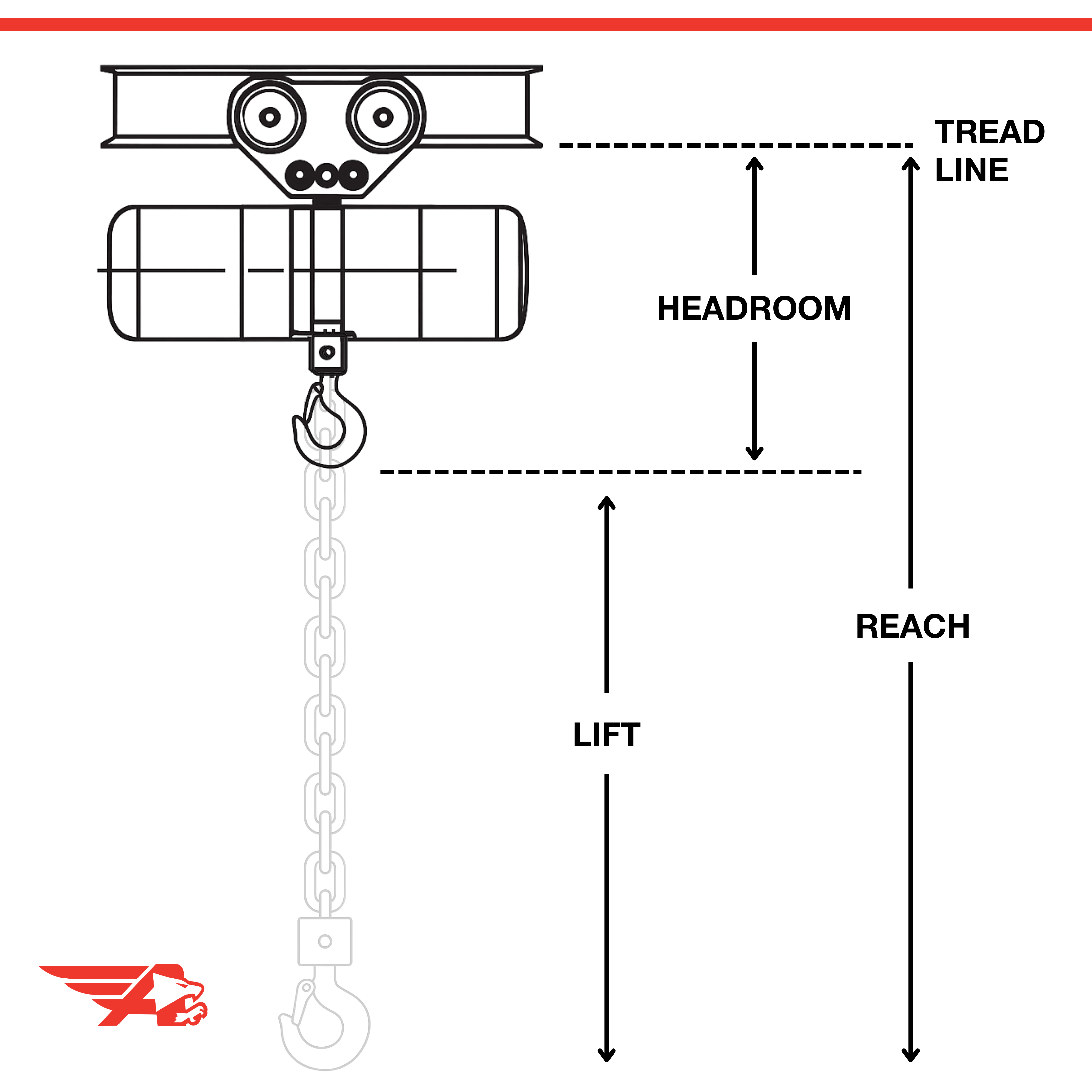

“Lift” refers to the distance the load hook travels vertically: from the lowest point the hook needs to reach to the highest point it must raise the load. Choosing the correct lift height ensures your electric chain hoist can move the load efficiently without wasting time, space, or money.

How to Calculate the Lift Distance (Hook to Hook)

To calculate chain length, start by identifying these two points:

- The lowest point the hook must reach: This could be the ground, a pit, or a platform.

- The highest point the hook must lift to: Usually just below the trolley or beam.

✅ Lift Height Formula: Highest lifting point (bottom of the top hook) – Lowest lifting point (surface/floor)

If your measurement is close, it’s best to round up rather than down. Chain that falls just short can disrupt workflow or require awkward repositioning. Adding a little extra lift ensures flexibility and helps prevent delays during operation.

For example, if your hoist will hang from a beam that is 22 feet above the floor and you need to lift items sitting on the ground, you’ll need at least a 22-foot lift height. In this case, a 20 foot chain hoist wouldn’t be long enough. Instead, you’d want to select a model with a 25-foot lift to give yourself a safe margin.

Still unsure about the chain length for your electric chain hoist? Our team can help you calculate it and make sure you get a hoist that’s properly sized for the job.

3. Power: Determine the Correct Power Supply for Your Electric Chain Hoist

Wire rope hoists are often larger and more industrial by default, so they are almost always three-phase. In contrast, electric chain hoists are more versatile and are powered by either single-phase or three-phase electrical systems. Want to explore whether a wire rope hoist might be best for your job? Read our guide on Electric Chain Hoists vs. Wire Rope Hoists.

While three-phase power is more common in industrial settings and comes with performance benefits, it's not available in every facility. And if your building doesn’t already have three-phase power installed, a three-phase hoist simply won’t work.

Before you choose between a single or three-phase electric chain hoist, you need to verify what power supply is available at your location.

Single-Phase vs. Three-Phase Power: Pros, Cons, and Common Applications

Single-Phase Power

- Found in most homes, smaller shops, garages, and light commercial buildings

- Supports lower capacity hoists, often up to 2 tons

- Simpler installation for locations without industrial power

- Ideal for occasional or light-duty lifting

Three-Phase Power

- Standard in manufacturing plants, warehouses, and industrial facilities

- Supports higher capacities and heavier duty cycles

- Provides smoother, more efficient power delivery with less motor strain

- Necessary for high-frequency or high-capacity lifting

Learn more about the advantages of three-phase vs single-phase hoists here.

In summary, if your job requires frequent lifting, faster speeds, or heavier loads, a three-phase electric chain hoist is the better choice, but only if it’s available on-site.

How to Match Voltage to Your Work Environment

Electric chain hoists are more likely to be installed in mobile or remote locations, so checking available voltage is critical before purchase. This part is simple but critical: don’t guess what kind of power you have. Check with your facility manager, maintenance team, or a licensed electrician to confirm the voltage available at your location.

Common industrial voltages include:

- 115V or 120V (single-phase)

- 208V, 230V, 240V, 460V, or 480V (three-phase)

Once you know what your location supports, you can confidently narrow your options to hoists built for that exact setup. Choosing the wrong voltage or phase will either lead to compatibility issues—or worse, damage the equipment.

✅ Tip: If you're ordering multiple hoists or outfitting a new facility, standardizing voltage across equipment can simplify maintenance and electrical setup.

4. Suspension: Select the Right Suspension Type For Your Electric Chain Hoist

Hook vs. Lug Mounted Electric Chain Hoists

Hook Mount

A hook suspension means that the hoist comes with a top hook designed to attach to a fixed point, allowing for quick and flexible installation. Hook mounts are best for lighter-duty or portable setups where the hoist might need to be removed or relocated.

Lug Mount

A lug mount means that the hoist is bolted directly to the trolley, creating a more stable and permanent connection. Lug-mounted hoists also reduce wear on the hoist frame, because the lug takes on the strain of movement instead of the hook swiveling under load

Trolley Types Used For Electric Chain Hoists

If you're planning to move your electric chain hoist along a beam, you’ll need to mount it to a trolley using a lug mount. From there, you'll need to choose the right type of trolley based on your specific job requirements.

Push Trolley

- Manually moved by pushing the load or hoist

- Best for light loads and short distances

- Ideal for hoists 2 tons or under

- Common in maintenance bays or workstations

Geared Trolley

- Operated by a hand chain that turns gears for smooth, controlled movement

- Great for precise load positioning

- Useful in areas with limited clearance or when exact alignment is needed

Motorized Trolley

- Powered by an electric motor, controlled by a pendant or remote

- Designed for heavier loads or frequent travel

- Often used with hoists 3 tons and up, or when load travel is part of a regular workflow

- Recommended for long runway beams or bridge crane systems

✅ Tip: If your team moves loads multiple times per shift or needs to travel more than a few feet regularly, investing in an electric chain hoist with electric trolley can reduce operator fatigue, improve efficiency, and extend equipment life.

5. Hoist Speed: Deciding Between Single-Speed and Dual-Speed Electric Chain Hoists

Not all lifting jobs require the same level of control. Choosing between a single-speed and a dual-speed electric chain hoist comes down to how much precision you need when positioning your load.

Single-speed hoists: One fixed lifting speed, typically around 8–16 feet per minute depending on capacity and motor. They're great for:

- General material handling

- Routine lifting and lowering tasks

- Maintenance, repair, and warehouse work

- Most day-to-day industrial applications

What Applications Require Dual-Speed Lifting or VFD-Controlled Lifting?

Dual-speed hoists are ideal when you need greater control over load placement, especially at the lower end of travel. They offer two fixed speeds: a faster speed to move the load efficiently, and a slower speed for precise placement near the drop point.

- You need to move heavy loads quickly, but slow down for final positioning

- Your material is not fragile, but requires precise alignment

- You want better control than a single-speed hoist but don’t need full VFD-level sensitivity

- Common in general assembly, mold placement, battery lifting, or maintenance

VFD-controlled hoists allow for smooth, gradual acceleration and deceleration, with no abrupt shifts between speeds. This near-seamless control minimizes shock load, sway, or bounce—especially important when handling fragile or high-value materials.

- You’re working with fragile materials that could be damaged by sudden stops or speed shifts

- You need ultra-smooth transitions throughout the lift

- Ideal for electronics, glass, precision tooling, or sensitive mechanical components

6. Environment: Choose The Right Electric Chain Hoist For Your Environment

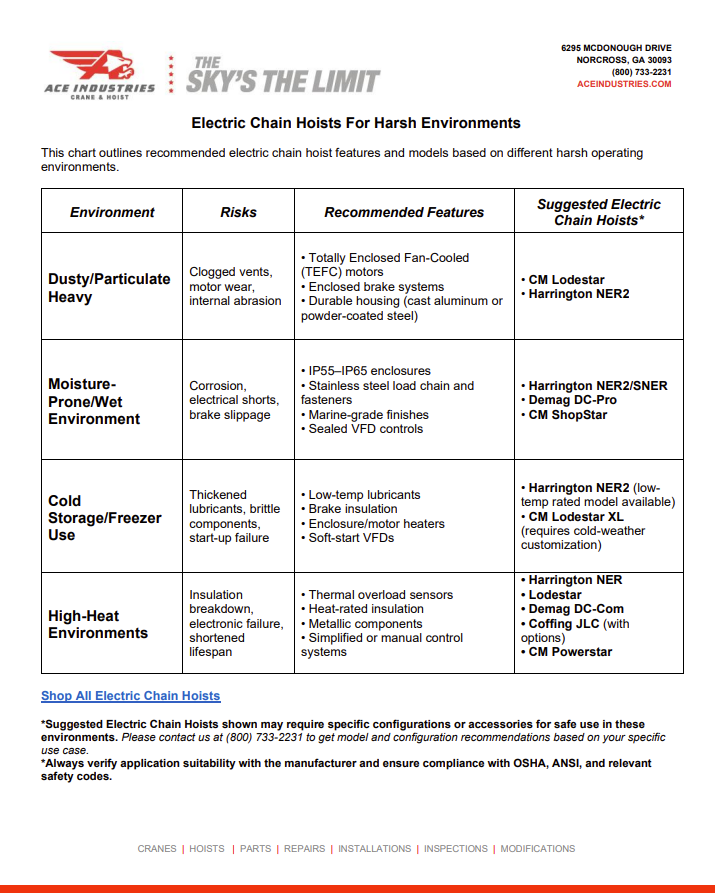

Environmental conditions like moisture, dust, extreme temperatures, and even exposure to chemicals can all affect the safety, performance, and lifespan of an electric chain hoist.

Dusty job sites can clog vents and wear down components, while moisture-prone areas may risk corrosion or short-circuiting if not properly sealed. Cold storage environments may require specialized lubricants or thermal protection, while high-heat areas can reduce the lifespan of electrical parts. Choosing a hoist with the right protection level—such as sealed motors, stainless steel components, or weather-rated enclosures—not only prevents downtime and safety issues, but also ensures electrical performance remains stable.

Using An Electric Chain Hoist Outdoors

We often get asked, "Would I be able to use an electric chain hoist outdoors?" The answer is yes—but only if it's rated for outdoor use or properly equipped with weather protection. That being said, there’s no such thing as a fully “waterproof” electric hoist. Even the toughest models will degrade faster when exposed to rain, salt, or constant temperature swings. But with the right specs and setup, some hoists can hold up outdoors or in harsh conditions far better than others. If you need a hoist for outdoor applications, look for models with:

- Totally Enclosed Fan-Cooled (TEFC) Motors: Protect internal components from dust and debris; suitable for outdoor use with added weather protection. Additionally, when selecting an electric chain hoist for outdoor applications, customers should consider: TEFC motor.

- High IP Ratings: IP65 or IP66 is ideal for outdoor or washdown conditions.

- Weather-Resistant Enclosures: NEMA 3R or higher helps protect against rain, snow, and humidity.

- Optional Rain Covers or Weatherproof Kits: Add-on protection is available for indoor-rated hoists, though prolonged exposure still reduces lifespan.

- Heaters or Dehumidifiers: Helpful in humid or cold climates to prevent condensation inside the hoist.

✅ Tip: Just because a hoist doesn’t come weather-ready doesn’t mean you can’t use it outside. In many cases, we can add the proper protection during configuration. Reach out to our team—we’ll make sure it’s set up right.

That said, there are a lot of variables that come into play — humidity, exposure level, frequency of use, temperature swings, etc. In some cases, IP55 might be sufficient for outdoor use, but it really depends on the setting. Because of that, we strongly recommend contacting one of our hoist specialists to ensure the selected equipment is suitable for the specific environment and application.

Want an electric chain hoist for a harsh environment?

Not every job happens in a clean, climate-controlled shop, and your electric chain hoist needs to reflect that. This downloadable chart outlines what features to look for based on your environment, and gives you model recommendations that stand up to harsh conditions when properly configured.

7. Support Structure: Match the Electric Chain Hoist to Your Support Structure

Choosing a Hoist for Gantry Cranes, Jibs, Monorails, and More

Your support structure determines how your hoist mounts, moves, and performs. Whether you're using an existing beam or installing a new system, here's what to consider:

1. Overhead I-Beam or Wide Flange Beam: If you have an existing beam:

- Trolley-mounted hoists allow horizontal travel. Choose push, geared, or motorized depending on usage.

- Hook suspension works if you already have a compatible trolley or beam clamp, but allows more sway.

- Check: Flange width and thickness to ensure trolley compatibility.

2. Gantry Cranes: Want an electric hoist for gantry crane? This option is ideal for mobile lifting, often outdoors or in open bays.

- Use trolley-mounted hoists for smooth travel along the gantry beam.

- Ensure the beam supports both load weight and hoist weight, including dynamic loads.

- Check: Beam capacity, indoor/outdoor rating, and grounding if used outside.

3. Workstation Cranes or Jib Cranes: Common in shops and light assembly areas.

- Workstation cranes need compact, low-headroom hoists with smooth operation.

- Jib cranes (especially articulating) perform best with lightweight hoists and matching trolley types.

- Check: Swing range, ceiling clearance, and power setup (festoon or conductor bar).

4. Ceiling-Mounted or Low Headroom Areas: For low clearance or obstructed ceilings:

- Use low-headroom hoists with integrated trolleys.

- Lug-mounted hoists can reduce vertical space compared to hook mounts.

- Check: HVAC, lighting, or sprinkler clearance.

5. No Overhead Support: If there’s no structure to hang from:

- Install a freestanding gantry, jib, or workstation crane rated for your load.

- Never hang a hoist from an unverified structure—it must be engineered and OSHA-compliant.

- Work with a qualified installer or structural engineer for safety.

✅ Tip: Confirm your beam dimensions (flange width, beam profile) before selecting a trolley-mounted hoist.

8. Determine the Right Electric Chain Hoist Model

At this point, you've seen just how many factors go into choosing the right electric chain hoist. The truth is, even the best hoist will disappoint if it’s not the right fit for the job.

We’ve seen customers invest in top-tier equipment, only to discover it doesn’t align with how they work. Maybe the hoist doesn’t travel far enough. Maybe the power source doesn’t match. Maybe it lifts just fine but can’t place a load precisely. The problem isn’t the product, it’s the mismatch between the hoist and the application.

Our Tried & True Top Recommendations

There’s a lot to consider when choosing the right electric chain hoist, but if you’re looking for a solid short list and starting point, we’ve put together a list of our tried-and-true favorites.

After decades of testing and installing electric chain hoists across every kind of job site and facility, these are the four models we consistently recommend for their performance, reliability, and long-term value.

Want to explore your options?

Shop all electric chain hoists and filter by features like brand, capacity, power supply, speed, to find the right hoist for your needs.

Still not sure which electric chain hoist is the right match? We can help.

At Ace Industries, we’ve worked with every type of electric chain hoist: from compact units for tight maintenance spaces to high-capacity VFD models for 24/7 production lines. Our experts can walk you through the options, explain trade-offs, and make sure you choose a hoist that works as hard as you do.

Give us a call at (800) 733-2231 or contact us here.

We’re here to make sure you get a hoist that fits your job, your budget, and your peace of mind.

Frequently Asked Questions

What are the safety features included in electric chain hoists?

Safety features can vary depending on the hoist model and how it’s designed to be used. At Ace Industries, we load test each electric chain hoist to 125% of its rated capacity before it leaves our distribution center to ensure it’s working safely and reliably.

Most electric chain hoists meet or exceed OSHA and ASME safety standards, but the exact features differ by brand and series. Some, like the Harrington ER, include both a motor brake and a load brake for added protection.

If you need something more specialized, like a hoist for food-grade environments, hazardous locations, or extra safety controls, just give us a call at (800) 733-2231. We’ll help you find the right hoist for your job.

What electric chain hoist parts typically need replacing first?

The most commonly replaced parts on electric chain hoists include:

- Load chain: Wears over time, especially if not lubricated or cleaned regularly

- Brake components: Mechanical or load brakes can wear down with repeated use

- Contactors or control switches: May degrade in high-use environments

- Hook latches or swivel hooks: Can bend or wear with improper loading

Regular inspections and preventive maintenance help you catch these early before they cause downtime. We also stock replacement parts for all major brands.

How do I find a part for a hoist?

If you want to explore electric chain hoist parts for the model you have, navigate to our Hoist Parts directory. Select the brand of your hoist, then choose the model. You’ll be able to view exploded part diagrams that make it easy to find the exact part you need—just click on the part to purchase it directly.

Can I retrofit my current setup with an electric chain hoist?

Often, yes. If your existing system uses a compatible beam size, trolley setup, or power supply, retrofitting is usually straightforward. In some cases, you may need to modify mounting brackets or upgrade the trolley. If you're switching from a manual hoist or wire rope hoist, we'll help you confirm compatibility and recommend a hoist that fits your structure and voltage.

Can I use an electric chain hoist outdoors?

Yes, but only if it’s rated for outdoor use. Look for a hoist with a high IP rating (IP55 or higher) to protect against dust and water. Models with NEMA 3R or 4 enclosures and corrosion-resistant finishes are ideal. Standard indoor hoists may fail quickly if exposed to rain, humidity, or extreme temperatures.

If your hoist doesn’t already have weather protection, there may be options to add it. Call us at (800) 733-2231 to find out what upgrades or accessories are available for your setup.

What is a low-noise electric chain hoist option? What should I consider for noise-sensitive environments?

For quieter operation, look for hoists with helical gearing (such as the CM Lodestar), VFD-controlled lifting that softens starts and stops, or models specifically marketed as low-noise or quiet-duty like the Demag DC-Pro.

Since noise ratings aren’t always included in standard specs, feel free to contact our team for model recommendations based on your workspace needs.