Types Of Jib Cranes

Ace Industries manufactures and distributes a full line of premium industrial jib cranes. If you do not find what you are looking for, please call our specialists, they will be happy to help.

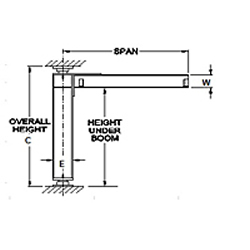

We also supply fittings for those interested in making their own wall bracket and wall cantilever jibs. We have jibs and components by CM, LiftTech, Yale, Gorbel, Spanco and others. Like our other products, there are no compromises. Heavy duty bearings provide smooth operation and long life. Optional bottom or top entry collectors provide trouble free electrification for 360 degree rotation. Motorized models are available. Standard capacities to 5 ton. Spans to 20 feet with 20 feet under the boom.

We find that the foundation requirements for free standing jib cranes are often underestimated. Standard footing requirements are shown on the free-standing jib dimension page.

The proper installation of a jib crane can easily exceed the cost of the equipment. A poor installation on the correct foundation or structure can cause problems. Difficulty in movement and undesired rotation after release can be dangerous to plant personnel. Have our expert technicians install your jibs to insure a satisfactory result.

Wall traveling jib cranes and other special applications are also available. Hoists and trolleys of every type and capacity are available from our stock to complete your jib crane project. This assures you of one source responsibility.

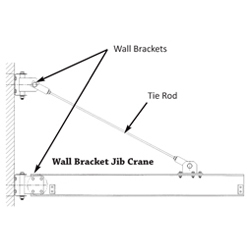

Wall BracketA wall bracket crane is one of the most popular types and is usually the least expensive of the alternatives. Application requirements for a wall bracket jib are that (1) there is a structurally sound wall or column to mount it on, and (2) there is sufficient clearance above the boom to accommodate the support rod that must be used. |

|

Standard Features

|

|

Free StandingFree Standing cranes are the most versatile type. They are perfect to place underneath large bridge cranes, in open areas where they can serve several work stations, in outdoor applications such as loading docks, or in machining and assembly operations where they can be overlapped with other jibs to provide staged operation. |

|

Standard Features

|

|

Wall CantileverA wall cantilever crane is one of the most popular types and is used when headroom is important requiring the jib boom to be located at the highest point possible to provide maximum lift for the installed hoist. Application requirements for a wall cantilever jib are that (1) there is a structurally sound wall or column to mount it on, and (2) there is sufficient clearance above the boom throughout its rotation arc. |

|

Standard Features

|

|

Mast TypeThe mast type crane is floor supported, top stabilized, and is capable of 360 degree rotation via a top and bottom bearing assembly. The following three requirements must be met before considering a mast type: An adequate structural support to support the crane at the top of the mast must exist. If the jib is installed underneath an overhead crane runway or building truss, then the deflection of the supporting member may not exceed 1/2 inch. Clearance overhead for the pivot assembly must exist. Clearance overhead for the boom to rotate must exist. |

|

Standard Features

|

|